ASPECT Technical Description

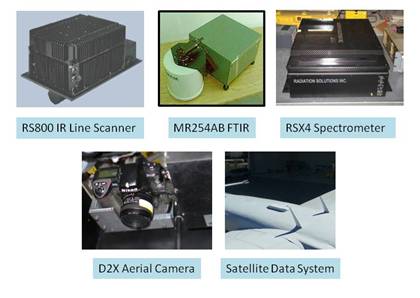

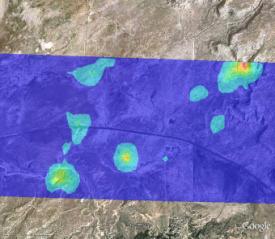

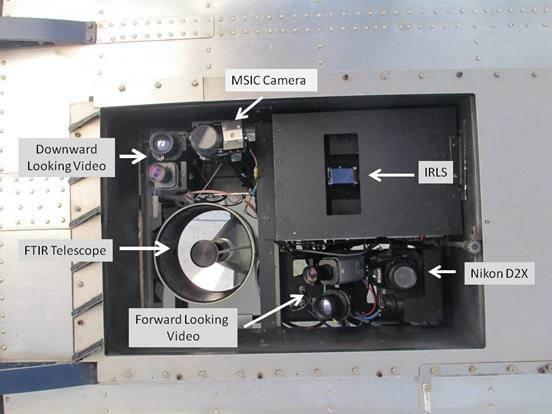

The ASPECT sensor suite (Figure 1) is mounted

in a fixed wing aircraft and uses the principles of remote hazard detection to

image, map, identify, and quantify chemical vapors and deposited

radioisotopes. Chemical plume measurements

are made at a rate of about two square miles per minute. The system normally operates at an altitude

of 2800 feet above ground level (AGL) and results in a high IR spatial

resolution of 0.3 meters. A simplified

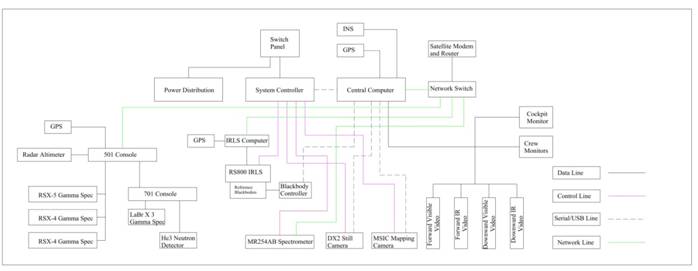

system diagram is provided in Figure 2.

The radiological data is collected between 300 and 500 feet AGL with a

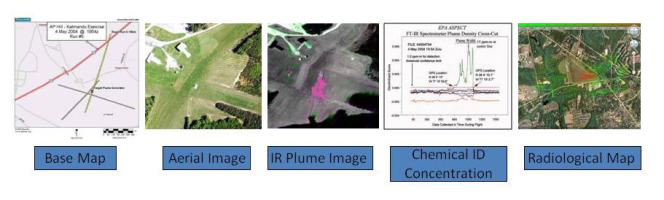

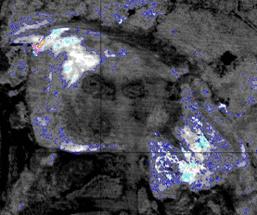

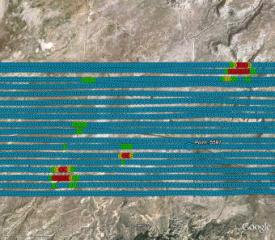

collection time of once per second and a field of view about 600-1000 feet. Situational awareness is provided by using

both high-resolution aerial digital photography and digital video that are

concurrently collected with chemical and radiological data and forms the basis

for a geographical information system data cube with several layered data

products (Figure 3). Efficient mission

execution requires that data is processed on-board the aircraft for

transmission or hand-off to the first responder. To facilitate data transmission while in

flight status, the aircraft is equipped with a broadband high-speed satellite

data communications system. With a

combination of onboard data processing and the satellite communication system,

selected airborne situational data sets are ready for dissemination to the

incident command team in less than 5 minutes after collection.

FIGURE 1 Sensor Suite

NOTE:

Images of the neutron detector and LaBr detectors are not shown. The aircraft is equipped with three RSX-4

units, only one is shown in this figure.

FIGURE 2 -

Simplified ASPECT System Diagram

FIGURE 3 Data Products

1.

Airframe

The ASPECT sensor suite is

operated from a single engine Cessna 208B Cargo Master aircraft (Figure

4). The aircraft and crew are certified

for full instrument flight rules (IFR) flight operations. This aircraft is equipped with one 20 X 30

inch belly hole with a retractable bay door.

All sensor systems are mounted on vibration isolated base plates

positioned over the belly hole. The

aircraft can operate from any airport having a 3000 ft runway and can stay

aloft for 5 hours. Technical

specifications for the program airframe are contained in Table 1.

FIGURE 4

ASPECT Aircraft, N9738B

TABLE 1

N9738B Technical Specifications

|

Tail: |

N7938B |

|

System: |

Single

Engine Turbo-Propeller Driven Aircraft |

|

Make: |

Cessna 208B

Cargo Master, Part 91 Certification |

|

Power

Plants: |

Pratt and

Whitney PT-6A-114 turbine driven three blade propeller, 600 shaft HP |

|

Empty

Weight: |

4458 lbs. |

|

Useful

Weight: |

4604 lbs. |

|

Maximum

Take-off Weight: |

9062 lbs. |

|

Typical

Cruise Speed: |

160 Kts |

|

Typical

Flight Duration: |

6 Hours

(65% Power) Plus 45 Minute Reserve |

|

Service and

Ceiling: |

Low

Altitude Waiver, 25000 Ft (MSL) max altitude |

|

Cabin: |

Un-pressurized,

Crew Oxygen |

|

Portals: |

One, 20 X

30 inch STC sensor hole with Remote

Door |

|

Avionics |

GPS IFR

Package GPS

navigation system for programmed flight lines Terrain/Obstacle

Avoidance Equipped Radar

Altimeter Equipped Dual

weather Radar, Live Weather Feed Dual VOR

Equipped, Dual Comms Equipped Dual

Transponders |

|

Electrical

Buss: |

Primary, 28

vdc @ 200 amps full load Secondary,

28 vdc @ 90 amps full load |

|

Data

Communication: |

Phased

Array Satellite System, 40-60 KB/sec Data/Telephone combined |

|

Readiness

Status: |

24/7/365 |

2.

Chemical Detection Capabilities

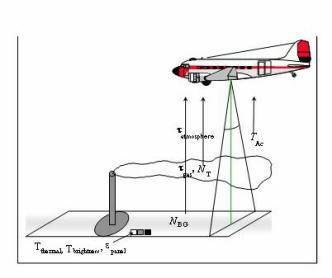

The principle of remote

detection, identification, and quantification of a chemical vapor species is

accomplished using passive infrared spectroscopy. Most vapor compounds have unique absorption

spectral bands at specific frequencies in the infrared spectral region. An asymmetric stretching between two atoms in

a molecule results in a fundamental frequency of vibration. Passive infrared measurements of a vapor

species are possible due to small thermal radiance differences between the

temperature of the chemical plume and a particular infrared scene background

(Figure 5). Both the cloud and the

atmosphere contribute to the total emitted radiance measured by an infrared

sensor. Careful monitoring of the change

in total infrared radiance levels leads to concentration estimations for a

particular vapor species. Concentration

times path length estimations are obtained based on the molar absorptivity for

each vapor species.

FIGURE 5 -

Principles of Remote Infrared Detection

A.

RS800IRLS Infrared Imager Sensor

The ASPECT Program uses a

modified Raytheon RS800 infrared line scanner to generate wide area chemical

imagery (Figure 6). This system

incorporates a unique detector assembly consisting of 16 cryogenically cooled

optical band pass filters affixed to a focal plan array. Scanning is accomplished with an integrated

rotating prism controlled by a feedback motor scan controller. Each rotation of the prism sweeps an angular

field of view of 60 degrees resulting in 1500 data points. When the scan rate is coupled to the normal

110-knot ground speed of the aircraft, a scan swath of 0.5 meters is

collected. This collection geometry

outputs a square data pixel 0.5 X 0.5 meters square. Radiometric calibration is performed during

each prism rotation by viewing two reference blackbodies mounted on either side

of the unit. Image registration is

accomplished during post processing by incorporating pitch and roll data

collected from an integrated gyroscope mounted on the scanner body. An integrated GPS receiver is used in the

processing step providing geo-registration of each pixel in the finished image

product. Detailed specifications of the

RS800IRLS are contained in Table 2.

FIGURE 6 -

RS800IRLS Line Scanner

TABLE 2 -

RS800IRLS Technical Specifications

|

System: |

TI

Systems/Raytheon RS800 MSIRLS |

|

Detector: |

Cryogenically

cooled focal plane array with integrated cold optical filters |

|

Spectral

Coverage: |

3 5

micrometer (mid-wave) and 8 12 micrometer (long-wave) |

|

Number of

Spectral Channels: |

16 total, 8

mid-wave and 8 long-wave |

|

Spectral

Resolution: |

5 to 20

wave numbers, channel dependent |

|

Spatial

Resolution: |

Better than

1.0 mill radian |

|

Scan Rate: |

60 Hz |

|

Radiometric

Calibration: |

Two

flanking blackbody units |

|

Field of

View (FOV): |

60 Degrees |

|

Thermal Resolution |

0.05 Degree

C. |

|

Linear

Range |

0 to 200

Degree C |

|

Pixel

Resolution (IFOV): |

0.5 meters

@ 850 meter collection altitude (AGL) |

|

Cross Field

Scan Coverage: |

980 meters

@ 850 meter collection altitude (AGL) |

|

Attitude

Stabilization: |

25 Hz pitch

and roll providing stabilized video |

|

Power: |

28 vdc @ 10

amps full load |

|

Weight: |

27 Kg (60

lbs.) |

|

Spin-up

Time: |

Less than

12 minutes (including cyro-system) |

|

Standard

Outputs: |

2 Channels

of stabilized RS-170 video, 16 channels of digitized (16 bit) spectral data,

1 channel of GPS (2 Hz) |

|

Data

Processing |

1 step full

radiometric image generation using an onboard algorithm. Approximately 1 minute processing time. |

B.

LS1600 Infrared Imager Sensor

A replacement infrared

imaging system is scheduled to be incorporated into the ASPECT system in December

2016 (figure 7). This system contains 16

regularly spaced long-wave channels ranging in spectral resolution of 15 to 30

wave numbers. By carefully selecting the

placement and bandwith of these channels, the program is constructing a low

resolution spectrometer permitted pattern recognition techniques to be applied

to the resulting imagery. These system

enhancements (over the RS800) will provide a factor of 2 to 5 sensitivity

improvement translating to chemical image detection at much lower

concentrations. Design and interim

construction specifications are provided in table 3.

Figure 7 --

LS1600 Infrared Line Scanner Imaging System

TABLE 3

LS1600 Infrared Imager Technical Specifications

|

System: |

LR Tech

LS1600 Line Scanner |

|

Detector: |

Cryogenically

cooled focal plane array with integrated cold optical filters |

|

Spectral

Coverage: |

8 13.5 micrometer (long-wave) |

|

Number of

Spectral Channels: |

16 total,

all long-wave |

|

Spectral

Resolution: |

15 to 30

wave numbers, regularly spaced |

|

Spatial

Resolution: |

Better than

1.0 mill radian |

|

Scan Rate: |

60 Hz |

|

Radiometric

Calibration: |

Two

flanking blackbody units |

|

Field of

View (FOV): |

60 Degrees |

|

Thermal

Resolution |

0.05 Degree

C. |

|

Linear

Range |

0 to 200

Degree C |

|

Pixel

Resolution (IFOV): |

0.5 meters

@ 850 meter collection altitude (AGL) |

|

Cross Field

Scan Coverage: |

980 meters

@ 850 meter collection altitude (AGL) |

|

Attitude

Stabilization: |

1600 Hz pitch

and roll providing stabilized video |

|

Power: |

28 vdc @ 10

amps full load |

|

Weight: |

27 Kg (60

lbs.) |

|

Spin-up

Time: |

Less than

12 minutes (including cyro-system) |

|

Standard

Outputs: |

1 Channel

of stabilized RS-170 video, 16 channels of digitized (18 bit) spectral data,

with associated attitude and GPS data (5 Hz) |

|

Data

Processing |

1 step full

radiometric image generation using an onboard algorithm. Approximately 1 minute processing time. |

C.

IRLS - Chemical Image Processing

1.

Chemical Processing

Processing of chemical data

is divided into two broad categories including image processing and spectral

processing. Infrared chemical signatures

present a challenge in data processing due to the small signal to noise ratio

(SNR) of the chemical vapor between the sensor and the surface. It is not uncommon to have a SNR of less than

four in a typical vapor cloud. In order

to image such a weak signal, the collection system and detector must be

optimized for high collection efficiency and a small instantaneous field of

view. The ASPECT RS800IRLS meets both of

these requirements by using an F/1 high-speed optical train coupled to a

16-channel cold optical filter focal plane array. This configuration provides very high signal

throughput while maintaining a 1.0 mill radian spatial resolution. The use of cold optical band pass filters

directly mounted on the face of the focal plane array eliminates a large

portion of the self-radiance (noise) while minimizing the attenuation of wanted

signal content. Raw data is fully

radiometrically calibrated using a set of flanking blackbodies providing

radiance-adjusted imagery. Jitter

removal and band registration are accomplished using an automated algorithm

using an integrated 2 dimensional gyro and GPS feed. Final data is generated using an automated

geo-registration algorithm in either a geo-Tiff or a geo-Jpeg format. Processing can be accomplished while in

flight and requires about 30 seconds to 1 minute per image depending on

size. The completed imagery is compressed

and made available to ground user through the aircraft satellite link.

The vapor cloud, shown in

Figure 8, is captured in an infrared image collected by the RS800SIRLS

multispectral sensor at an industrial site in the Midwest. The detection limit of the vapor

concentration (shown in red) was determined to be less than 20 ppm/m while the

center cloud concentration was greater than 250 ppm/m. This image has been cropped with only 1/3 of

the actual sensor field-of-view being displayed. The original image width of

the image was approximately 1200 meters wide.

For the ASPECT application, the RS800IRLS system provides a qualitative

indication of the presence or

absence of a particular

chemical species. The detection limit

provided by the sensors is applicable to both chemical emergency response and

crisis mitigation following a terrorism event.

2.

Thermal Processing

Figure 9 shows a long wave

thermal image of an underground mine fire in Kansas City, MO. In this application, the calibrated

radiometric data from the RS800IRLS is processed to show direct surface

temperature. In the standard

configuration, the imager provides an automated linear temperature measure up

to about 200 oC at a

resolution of 0.05 oC. Higher temperature measurements in the order

of 500 oC are possible

by changing the input stop and detector of the instrument. As part of the thermal processing method,

solutions to the scene emissivity are solved and factored into the temperature

product.

FIGURE 9 - Thermal Image of an

Underground Mine Fire

3.

Oil

Detection Processing

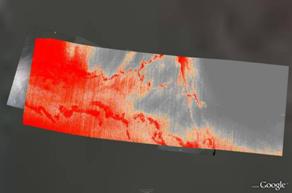

The ASPECT sensor system was

extensively used to detect oil on water during the Deep Water Horizon Oil

spill. The application of long wave IR

to detect oil has been known for a number of years and has advantages over

visible detection of oil including the ability to image oil under strong sun

angle (glint) and the ability to image oil at night. The primary problem of using long wave IR in

oil detection is centered on an accurate measure of the surface temperature with

a pixel size that is small enough to provide adequate scene dynamic range. Figure 10 shows an image that was processed

from oil on water in the open ocean. In

this setting, the surface temperature of the ocean is very constant. The image was formed by detecting the

difference in emissivity between 0.96 for water and 0.93 for oil. Weathered oil has an emissivity of 0.98 or

0.99 and was usually at a different surface temperature. This image was processed using the small

emissivity differential of oil and water as the primary discriminate, coupled with

weather oil having a different surface temperature.

By using a processing

technique that examined data value boundaries, the amount of oil on the water

surface was generated. Figure 11 shows

an image of oil on water in a near shore environment. For this environment, the thermal gradient of

the water in the shallows is much greater than the emissivity contrast of the

oil and water. A multi-dimensional

pattern recognition algorithm utilizing a pre-processing procedure known as

alpha residuals to eliminate the temperature difference was used to

discriminate oil and water. This

technique permitted detection and characterization of oil ranging from sheen to

thick oil.

FIGURE 10 - Open Water

Detection and Discrimination of Oil Using IR

FIGURE 11 - Detection and

Discrimination of Oil using Pattern Recognition

D.

MR254AB Spectrometer

Chemical vapor detection and

quantification is accomplished using a modified Bomen MR254AB spectrometer

(Figure 12). This custom designed

spectrometer utilizes a double wishbone pendulum interferometer providing both

high signal throughput and vibrational noise immunity. Two cryogenically cooled detectors provide

both mid and long wave operation.

Spectral resolution is selectable and ranges from 1 to 128 wave number

with 16-wave number normally used for automated compound detection. When operated at 16 wave number resolution,

the unit scans at 70 Hz providing a spatial sampling interval every 0.75 meters

along the ground track of the aircraft.

The program uses an automated compound detection algorithm based on

digital filtering and pattern recognition.

Geo-registration of each Fourier Transform Spectrometer (FTS) scan is

accomplished using a concurrent GPS input from the ASPECT main GPS receiver. Technical specifications of the FTS system

are contained in Table 4.

FIGURE 12 -

MR254AB FTS Spectrometer

TABLE 4 -

FTS Technical Specifications

|

System: |

Modified

Bomem MR-200 Series (MR-254AB) |

|

Detectors: |

Cryogenically

cooled Single Pixel Design |

|

Spectral

Coverage: |

InSb

Detector for 3 5 micrometer (mid-wave) MCT Detector for 8 12 micrometer

(long-wave) |

|

Noise

Figure |

Mid-wave

6x10-9 W/cm2-srcm-1, Long-wave 1.8x10-8

W/cm2-srcm-1 |

|

Spectral

Resolution: |

1 to 128

wave numbers, User selectable |

|

Spatial

Resolution: |

5

milli-radian (0.2o) thru 25.4 cm (10 inch) Primary Telescope, 0.75 meter interval at 110 kts collection

velocity |

|

Scan Rate: |

70 Hz @ 16 wave number resolution |

|

Field of

View (FOV): |

3 meters @

850 meter collection altitude (AGL) |

|

Radiometric

Reference |

Integrated

cold source (77o K) |

|

Targeting |

Calibrated

bore camera (Nadir) |

|

Power: |

28 vdc @ 8

amps full load |

|

Weight: |

40 Kg (90

lbs.) |

|

Spin-up

Time: |

Less than 4

minutes (including cyro-system) |

|

Standard

Outputs: |

2 Channels

of Grams format spectral data (16 bit), 1 channel of RS-170 video. |

|

Data Processing: |

1 Step

pattern recognition compound detection using onboard algorithms, approx. 30

60 seconds processing time after data collection. |

E.

VSR Spectrometer

The MR254AB spectrometer is

scheduled to be replaced in January 2017 with a two channel Versatile

SpectroRadiometer (VSR) (figure 13). The

VSR consist of a double wishbone interferometer with integrated calibration

blackbodies. The program is currently

conducting noise improvements to the

system by out boarding the cyro-pumps and upgrading the long wave detector to

include both a top hat and cold filter configuration. The goal of these activities is to improve

the noise figure of the instrument to a 2 to 5fold improvement over the

MR254AB Design and interim construction specifications

are provided in table 5.

Figure 13

VSR Spectrometer

TABLE 5 -

VSR Technical Specifications

|

System: |

VSR Double

Wishbone FTS System |

|

Detectors: |

Cryogenically

cooled Single Pixel Design |

|

Spectral

Coverage: |

InSb

Detector for 3 5 micrometer (mid-wave) MCT Detector for 8 12 micrometer

(long-wave) |

|

Noise

Figure |

Mid-wave

4.5x10-10 W/cm2-srcm-1, Long-wave

2.3x10-9 W/cm2-srcm-1 |

|

Spectral

Resolution: |

1 to 128

wave numbers, User selectable |

|

Spatial

Resolution: |

5

milli-radian (0.2o) thru 25.4 cm (10 inch) Primary Telescope, 0.75 meter interval at 110 kts collection

velocity |

|

Scan Rate: |

70 - 90 Hz @ 16 wave number resolution, rate

selectable |

|

Field of

View (FOV): |

3 meters @

850 meter collection altitude (AGL) |

|

Radiometric

Reference |

Integrated

blackbody sources (303o K and 328o K ), calibrated

after each measurement |

|

Targeting |

Calibrated

bore camera (Nadir) |

|

Power: |

28 vdc @ 8

amps full load |

|

Weight: |

40 Kg (90

lbs.) |

|

Spin-up

Time: |

Less than 4

minutes (including cyro-system) |

|

Standard Outputs: |

2 Channels

of Grams format spectral data (16 bit) |

|

Data

Processing: |

1 Step

pattern recognition compound detection using onboard algorithms, approx. 30

60 seconds processing time after data collection. |

F.

Spectral Processing

Spectral data processing

(signal processing) from the ASPECT MR-254AB spectrometer is processed using

background suppression, pattern recognition algorithm. Processing spectral data from a moving

airborne platform requires unique methods to balance weak signal detection

sensitivity, false alarm minimization, and processing speed. The background suppression, pattern

recognition methods associated with the ASPECT Program have been documented in

over 100 open literature publications.

One of the principal

weaknesses of airborne FTS data is the ability to reference each collected

spectra to a suitable background for subsequent spectra subtraction. While methods have been devised to accomplish

this procedure, typical airborne spectra show changes between successive scan

of several orders of magnitude due to changing radiometric scene

conditions. These scan-to-scan changes

render traditional background subtraction methods unusable for weak signal detection. The background suppression method used by

ASPECT circumvents this problem by using a digital filtering process to remove

the background component from the raw interferometer data. This approach is analogous to using the

tuning section of a radio receiver to preselect the portion of the signal for

subsequent processing. The resulting

filtered intermediate data maintains the weak signal components necessary for

subsequent analysis.

An additional weakness of

traditional FTS processing involves the need to provide a resolution high enough

to permit compounds exhibiting narrow spectra features to be matched with

published library spectra. This method

is initiated using the Fast Fourier Transform (FFT). While the FFT algorithm is very robust

mathematically, certain data collection requirements must be met to permit the

transform to be valid. In order to

provide high spectral resolution spectra, the length of the interferogram must

be matched to the desired resolution for the transform to work properly. This requirement forces a long collection

period for each interferogram and since the aircraft is moving, it is probable

that the radiometric scene being viewed by the spectrometer will change during

the collection of the interferogram. The

changing scene causes the FFT to generate spectral artifacts in the resulting

spectral information. These artifacts

are phantom signals that confuse and complicate subsequent compound

identification.

The standard matched filter

compound discrimination method likewise exhibits weak signal performance and

often generates false alarms due to common atmospheric interference. ASPECT solves these problems by using a

combination of digital band pass filtering followed by a multi-dimensional

pattern recognition algorithm. The

digital filters and pattern recognition coefficients are developed using a

combination of laboratory, field, and library data and folded into a training

set that is run against unknown data.

Digital filters can be readily constructed which take into account both

spectrometer line shapes and adjacent interferents, greatly improving the weak

signal system gain. The pattern

recognition algorithm processes the filter output in a multi-space fashion and

enhances the selectivity of the detection.

These methods are very similar to a superheterodyne receiver that uses

band pass adjustable intermediate filters followed by a DSP

detector/discriminator such as in a modern radar system. Since the methods use relatively simple

computational operations, signal processing can be accomplished in a few

seconds. Finally, as data is processed,

the position of the detection is referenced to onboard GPS data providing a GIS

ready data output. Table 6 lists the

compounds (and a 10 meter equivalent path length detection limit) that are

currently installed in the airborne library using the digital filtering/pattern

recognition method.

A unique feature of the

ASPECT System includes the ability to process spectral data automatically in

the aircraft with a full reach back link to the program QA/QC program. As data is generated in the aircraft using the

pattern recognition software, a support data package is extracted by the reach

back team and independently reviewed as a confirmation to data generated by the

aircraft.

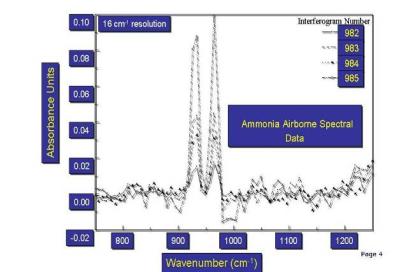

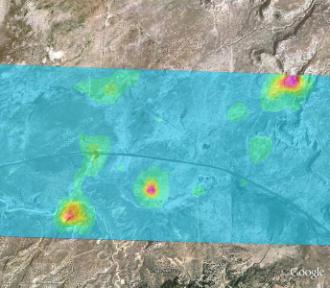

Figure 14 shows airborne

absorbance spectra of ammonia vapor collected from an ammonium nitrate fire

using the MR-254AB spectrometer. This

spectrum was generated by carefully selecting a suitable background spectra and

conducting a traditional background subtraction, a time consuming operation. Figure 15 shows the same data processed using

the automated background suppression/pattern recognition method. Ammonia detection is clearly

demonstrated. Figure 16 shows how these

detections are referenced to a real-world geographical map. Individual detection locations corresponding

to FTS scans are mated with latitude and longitude coordinate values.

TABLE 6 - Chemicals

Included in the ASPECT Auto-Processing Library

|

Acetic Acid

(2.0) |

Cumene

(23.1) |

Isoprene

(6.5) |

Propylene

(3.7) |

|

Acetone

(5.6) |

Diborane

(5.0) |

Isopropanol

(8.5) |

Propylene

Oxide (6.8) |

|

Acrolein

(8.8) |

1,1-Dichloroethene

(3.7) |

Isopropyl

Acetate (0.7) |

Silicon

Tetrafluoride (0.2) |

|

Acrylonitrile

(12.5) |

Dichloromethane

(6.0) |

MAPP (3.7) |

Sulfur

Dioxide (15) |

|

Acrylic

Acid (3.3) |

Dichlorodifluoromethane

(0.7) |

Methyl

Acetate (1.0) |

Sulfur

Hexafluoride (0.07) |

|

Allyl

Alcohol (5.3) |

1,1-Difluoroethane

(0.8) |

Methyl

Ethyl Ketone (7.5) |

Sulfur

Mustard (6.0) |

|

Ammonia

(2.0) |

Difluoromethane

(0.8) |

Methanol

(5.4) |

Nitrogen

Mustard (2.5) |

|

Arsine (18.7) |

Ethanol

(6.3) |

Methylbromide

(60) |

Phosgene

(0.5) |

|

Bis-Chloroethyl

Ether (1.7) |

Ethyl

Acetate (0.8) |

Methylene

Chloride (1.1) |

Phosphine

(8.3) |

|

Boron

Tribromide (0.2) |

Ethyl

Formate (1.0) |

Methyl

Methacrylate (3.0) |

Tetrachloroethylene

(10) |

|

Boron Triflouride

(5.6) |

Ethylene

(5.0) |

MTEB (3.8) |

1,1,1-Trichloroethane

(1.9) |

|

1,3-Butadiene

(5.0) |

Formic Acid

(5.0) |

Naphthalene

(3.8) |

Trichloroethylene

(2.7) |

|

1-Butene

(12.0) |

Freon 134a

(0.8) |

n-Butyl

Acetate (3.8) |

Trichloromethane

(0.7) |

|

2-Butene

(18.8) |

GA (Tabun)

(0.7) |

n-Butyl

Alcohol (7.9) |

Triethylamine

(6.2) |

|

Carbon

Tetrachloride (0.2) |

GB (Sarin)

(0.5) |

Nitric Acid

(5.0) |

Triethylphosphate

(0.3) |

|

Carbonyl

Chloride (0.8) |

Germane

(1.5) |

Nitrogen

Trifluoride (0.7) |

Trimethylamine

(9.3) |

|

Carbon

Tetraflouride (0.1) |

Hexafluoroacetone

(0.4) |

Phosphorus

Oxychloride (2.0) |

Trimethyl

Phosphite (0.4) |

|

Chlorodifluoromethane

(0.6) |

Isobutylene

(15) |

Propyl

Acetate (0.7) |

Vinyl

Acetate (0.6) |

FIGURE 14 - Ammonia

Spectra

FIGURE 15 -

Ammonia Detected with Pattern Recognition

FIGURE 16 - Locations of

Ammonia Detection

Quantitative compound

specific information is also generated using the MR-254AB spectrometer. This application uses a multi-dimensional

model generated using radiometric, thermal, and concentration calibrated

laboratory data for each compound in the airborne library. As with compound detection methods, multiple

publications have documented the feasibility of using this approach to remotely

quantify chemical vapors. The first open

literature scientific peer reviewed paper was completed using the ASPECT

method.

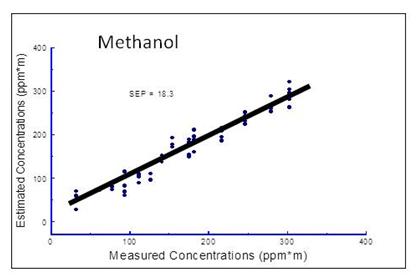

Figure 17 shows the estimated

concentration of methanol measured by ground sensors and compared with the

remotely collected FT-IR data. The data

shows a standard error of prediction of 18 ppm-m for a range of concentration

between 20 to 400 ppm-m. This range of

concentrations is consistent with both hazardous vapor releases and terrorist

concerns.

Figure 17 - Quantitative Methanol Results

3.

Radiological Detection Capabilities

A. RSX4 Sodium

NaI Gamma Ray Spectrometers

Airborne radiological

measurements are conducted using three fully integrated multi-crystal sodium

iodide (NaI) RSX4 gamma ray spectrometers (Figure 19). Each RSX4 spectrometer contains four

4x2x16 doped NaI crystals each having an independent photomultiplier/

spectrometer assembly. One RSX unit is

configured with an additional upward NaI crystal utilized to provide real-time

cosmic ray correction. Count and

energy data from each crystal and pack is combined using a self-calibrating

signal processor to generate a virtual detector output. All spectrometer packs are further combined

using a signal console controlled by the on-board computer in the

aircraft. Due to the advanced signal

processing techniques unique to the RSX4 units, very high total count rates

(approximately 1 million counts per second) can be discriminated and processed. Specifications of the RSX4 spectrometers can

be found in table 8.

B.

Lanthanum Bromide Gamma Ray

Spectrometers

High resolution gamma ray

detection is provided using a set of three 3 x 3 lanthanum bromide (LaBr)

crystals all ganged into a single virtual detector. This configuration of detector has a much

lower efficiency but has a much higher degree of spectral resolution than the

NaI spectrometers. Accordingly, the LaBr

crystal are most often used in complex isotope environments having a higher

intensity such as in a fall-out field resulting from a nuclear accident.

Neutron detection is provided

using a set of two, four bundle straw neutron detectors. These systems do not use expensive and rare

He3 gas and are very rugged. Both

detectors are ganged into one virtual total count sensor. Radiological spectral data, GPS position,

and radar altitude are collected at a one-second interval at all times during a

survey. In order to provide optimal

collection geometry, flight line data is loaded into the aircraft flight

computer prior to conducting the survey.

Typical airborne surveys are flown at 300 to 500 feet AGL.

FIGURE 19 -

RSX4 Gamma Ray Spectrometer

C.

Neutron Detection

Proper spectrometer operation

and data quality assurance is maintained using both internal and external

calibration algorithms. A self-contained

internal calibration algorithm acts as a watchdog and continuously monitors the

spectrometer systems for proper system operation and data output. If any errors are encountered with a specific

crystal and/or spectrometer pack during the collection process an error message

is generated and the data associated with that crystal are removed from further

analyses. External calibration

procedures are routinely executed and consist of both designed data collection

over characterized areas and pad calibrations over known quantities of

radiological doped concrete. Technical

specifications for the RsX4 gamma ray spectrometers are contained in Table 8.

TABLE 8 -

RX4 Technical Specifications

|

System: |

RSI RSX4

Gamma Ray Spectrometer |

|

Detector:

Gamma Ray |

4 Doped NaI

Detectors per pack, 3 Packs, 2x4x16 inch crystals, |

|

Detector:

Cosmic Ray |

One 2x4x16

upward crystal integrated into one of the RSX units. |

|

Total NaI Detector

Volume: |

25 liters |

|

Energy

Coverage: |

0 3000

KeV |

|

Number of

Channels: |

1024 |

|

Energy

Resolution: |

Approx. 3

KeV per Channel |

|

Scan Rate: |

1 Hz |

|

Internal

Calibration: |

Automatic

based on Natural K, U, and T |

|

Field of

View (FOV): |

45 Degrees |

|

Cross Field

Scan Coverage: |

300 meters

@ 300 meter collection altitude (AGL) |

|

Altitude

Determination: |

2.4 GHz

Radar Altimeter, 10 Meter DEM Database |

|

Power: |

28 vdc @ 4

amps full load (3 Packs) |

|

Weight: |

136 Kg (300

lbs.) |

|

Spin-up

Time: |

Less than 5

minutes |

|

Standard

Outputs: |

1024 Gamma

Ray Spectra, GPS (2 Hz) |

|

Data

Processing |

1 Step Full

Processing of Total Count, Sigma, and Exposure Rate, Approximately 1 minute Processing Time

After Data Collection. |

D.

Radiological Data Processing

All radiological data is

processed automatically using airborne algorithms. Normally, a specifically designed survey

flight path is flow by the aircraft and once complete, a suite of radiological

products is generated from the collected data.

Since radiological sources are universally present from the earth and

from cosmic sources, all radiological data must be corrected to establish a

baseline measurement. Cosmic estimates

are established by flying the aircraft 3000 feet AGL while collecting gamma

spectral data. At altitudes of 3000 feet

and greater all radiological inputs are either from the cosmic sources or the

aircraft (which is a constant).

Quantified cosmic contributions are stripped out from all subsequent

data. Depending on the length of the radiological

survey, cosmic backgrounds may be collected at the beginning and end of the

survey. In a fashion similar to the

cosmic correction, the natural radiological background for the survey area is

also established. This process normally

calls for collecting a limited amount of data (a test line) at the survey

altitude (300 500 ft. AGL) in an area of similar geology/land use but outside

of the region of survey interest. By

subtracting the test line data from the survey data, a corrected radiation map

for the survey area is generated.

Several data products are

generated automatically by the system including total counts, a sigma map, and

an exposure map. The total count product

is generated by mapping the corrected total count data (approximately 30 3000

KeV) from the spectrometers using the integrated GPS data as the geographic

datum. Exposure Rate mps are normally

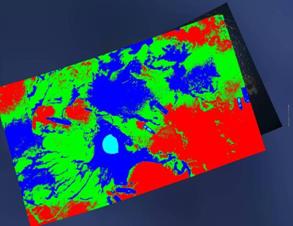

contoured at regular intervals in micro-Roentgens (µR). Figure 20 illustrates a typical survey total

count plot.

FIGURE 20 -

Total Count Plot

A second radiological product

includes an array of isotope specific sigma plots or maps. These plots are very useful to the first

responder since they help highlight specific data points that may require

detailed ground investigation. This

procedure consists of a two-step method with the first being a windowing for

selected isotope energies followed by a statistical treatment of the data. Isotope specific data is generated by

windowing the gamma spectrum at energy levels corresponding to the isotopes of

interest. As part of this analysis,

higher energy contributions from uranium and thorium are removed using a

stripping coefficient. A statistical

average and standard deviation is next computed for the entire survey area

using the isotope windowed data. Since

the standard deviation provides a measure of the variance of the data set, data

values showing several standard deviations (sigma) indicate that these values

are statistically different from the majority of the population. ASPECT uses a graded scale in which 0 to 4

sigma are considered normal and greater than 4 sigma highlights data very

different from the population. Greater

than 6 sigma indicates that the data is extremely different and warrants

additional investigation. By using

different isotope windows, a number of sigma maps can be generated for a given

survey (Figure 21).

The final set of products

generated by the gamma ray spectrometers consist of an exposure plot or

map. This procedure consist of

extrapolating the measured total count data collected at the flight altitude

down to the total count that would be measured 1 meter above the surface. This method utilizes a weighting algorithm

that provides more focus on the high energy counts since these represent the

most energetic and penetrating gamma rays.

The extrapolation process is accomplished using the calibration

coefficients developed as part of the exterior calibration process. The resulting data is plotted in µR/hr and

provides the first responder with a health-based estimate of radiological

dosage at the ground surface (Figure 22).

FIGURE 21 -

Sigma Plot

FIGURE 22 -

Exposure Plot

4.

Aerial Camera Systems

A.

Nikon D2X

ASPECT utilizes a still

digital Nikon DX2 camera to collect and provide visible aerial imagery as part

of the core data product package (Figure 23). The DX2 consists of a 12.4 mega

pixel CMOS camera supporting a 3:5 aspect ratio frame. The system uses a 28 mm

wide-angle lens and is slaved to the primary IR sensors and provides concurrent

image collection when the other sensors are triggered for operation. All

imagery is geo-rectified using both aircraft attitude correction (pitch, yaw,

and roll) and GPS positional information. Imagery can be processed while the

aircraft is in flight status or approximately 600 frames per hour can be

automatically batch processed once the data is downloaded from the aircraft.

Technical specification for the DX2 camera is provided in Table 8.

Figure 23: ASPECT Camera Suite

TABLE 8 -

DX2

Aerial

Digital Camera Technical Specifications

|

System: |

Nikon DX2

Camera Body |

|

Detectors: |

12.4-megapixel

digital CMOS sensor |

|

Aspect

Ratio: |

3:5 |

|

Lens: |

28 mm

Digital Compatible |

|

Field of

View (FOV): |

824 meters

Cross flight and 548 meters Direction of Flight @ 850 meter collection

altitude (AGL) |

|

Pixel

Resolution (IFOV): |

19.2 cm @

850 meter collection altitude (AGL) |

|

Frame

Timing and Collection Rate: |

Operator

Selectable, 3 to 8 seconds, Approximately 600 frames per hour |

|

Trigger

Control: |

Automatic,

Manual, and Slave |

|

Power: |

12 vdc @ 1

amp full load |

|

Spin-up

Time: |

Less than 2

minutes from System Start |

|

Standard

Outputs: |

JPEG, Tiff |

|

Data

Processing: |

Full

INS/GPS Geospatial Rectification |

B.

Imperx MSIC

The Nikon DX2 is scheduled to

be replaced in December 2015 with an Imperx mapping camera (figure 24). The new mapping camera will provide a similar

aspect ratio and aerial coverage at a much higher resolution. Due to the size of the CCD sensor, little

edge distortion will be present in the frames.

Technical specification for the mapping camera is shown in table 9.

Figure 24

Imperx Mapping Camera

TABLE 9 -

Imperx Aerial Digital Camera Technical Specifications

|

System: |

Imperx

B6640 body |

|

Detectors: |

29-megapixel

digital CCD sensor (KAI-29050) |

|

Aspect

Ratio: |

4:5 |

|

Lens: |

24 mm

Digital Compatible |

|

Field of

View (FOV): |

824 meters

Cross flight and 548 meters Direction of Flight @ 850 meter collection

altitude (AGL) |

|

Pixel

Resolution (IFOV): |

92 cm @ 850

meter collection altitude (AGL) |

|

Frame

Timing and Collection Rate: |

Operator

Selectable, 1 to 15 seconds, Approximately 600 frames per hour for normal

mission |

|

Trigger

Control: |

Automatic,

Manual, and Slave |

|

Power: |

12 vdc @ 1

amp full load |

|

Spin-up

Time: |

Less than 2

minutes from System Start |

|

Standard

Outputs: |

JPEG,

TrueSense |

|

Data

Processing: |

Full

INS/GPS Geospatial Rectification |

C.

Canon EOS Oblique Camera

In order to provide

situational information from the perspective of the flight crew, ASPECT also

supports an oblique camera system that is operated from the right side of the

aircraft. This camera consists of a Canon EOS Rebel digital SLR camera body

with a 30 120 mm variable zoom lens (Figure 25). Frames are collected at an

approximate the 2 oclock position relative to the aircraft with the target

approximately 1000 meters from the aircraft. Figure 7 provides examples of an

aerial (downward view) photo and an oblique (side view) photos. The aerial

photos are taken at an altitude of about 2,800 feet above the ground (AGL) and

the oblique photos are taken at lower altitudes ranging from 500 feet to about

1,200 feet AGL. Table 3 provides technical specification of the oblique camera

system.

Figure 25

-- Canon EOS Rebel Digital SLR Camera

TABLE 10 - Canon EOS Aerial Oblique

Digital Camera Technical Specifications

|

System: |

Canon

EOS Camera Body |

|

Detectors: |

6.3-megapixel

digital CMOS sensor |

|

Aspect

Ratio: |

3:5 |

|

Lens: |

30-120

mm zoom, Digital Compatible |

|

Trigger

Control: |

Manual |

|

Power: |

Internal

Battery |

|

Standard

Outputs: |

JPEG,

Tiff |

|

Data

Processing: |

Spatial

Geo-reference |

D.

Visible Imagery Data Processing

Visible imagery collected

with the ASPECT System is ultimately processed into a geo-registered jpeg or

tiff format image. Image processing is

composed of two primary steps including image enhancement and geo-registration. Both of these processing steps can be

processed while the aircraft is in flight status but typically, imagery is

processed once the aircraft lands due to the large quantity of data involved

with aerial photography. A standard

flight mission often generates 600 aerial images.

The ASPECT aerial camera

consists of a still frame 3x4 ratio digital camera. A wide field of view lens is utilized to

match the ground width coverage of the line scanner system. Due to the speed of the aircraft and the fact

that ASPECT may fly in low light conditions, the camera uses a fixed focus and

shutter speed configuration. Raw imagery

is subsequently processed to balance contrast and saturation of each

image. In addition, since a wide-angle

lens is used, edge distortion is corrected using a custom-built camera

model. Both of these overall algorithms

are executed automatically in a batch processing system.

The ASPECT camera is

fix-mounted to the primary optical base plate.

The camera axis is bore sighted to within 0.5 degrees to the axis

centers of the other optical systems.

While images are being collected, a concurrent system collects both GPS

data and inertial data to provide a high-resolution pitch, roll, and yaw

correction dataset. An automatic

software package merges these data set and geo-corrects each image using a

triangular correction mode. The

resulting images statistically show less than 11 meters of center frame

positional error and less than 1 degree of rotational error. As with the frame enhancement processing,

geo-registration is accomplished in a batch mode at a rate of approximately 800

images per hour. Following registration,

images can be directly used by the responder or further corrected with minor

positional and rotation corrections (Figure 26).

If requested by the data

user, aerial photography (and IR imagery) can be stitched into a wide area

mosaic. While this process does take

some time, a 4 square kilometer mosaic image (approximately 8 frames) can be

assembled in about 2 hours (Figure 27).

Oblique digital photography

is processed to capture the situational environment from the perspective of the

flight crew. All frames are collected

from the right side of the aircraft at approximately 45 degrees from the nose

of the aircraft. During automated

processing, GPS data is used to provide the position that the frame was

collected and the direction that the frame was collected is determined from the

track of the aircraft and the relative direction that the camera was operated

from within the aircraft. Figure 28

illustrates an example of an oblique image.

FIGURE 26 - Digital Aerial Visible

Imagery

FIGURE 27 -

Mosaic Imagery Product

FIGURE 28 -

Oblique Aerial Image

E.

Data Communication Technology

The ability to rapidly

transfer data from the ASPECT aircraft to the ultimate end user is mandatory if

the system is to support emergency response functions. ASPECT uses a state of the art

satellite-based communication system that provides broadband data through put

while the aircraft is in flight status (Figure 29). The system consists of an electronically

steered phase array satellite antenna coupled to a RF power amplifier/receiver

supporting a wired onboard computer TCP/IP modem/network. All components of the system have been

installed and certified as part of a formal FAA STC procedure. The system utilizes a geosynchronous

satellite connection and permits full rate communication throughout the

contiguous U.S. Table 11 contains the

technical specifications for the satellite communications system.

FIGURE 29 -

Satellite Communication System Phased Array Antenna

TABLE 11 -

Satellite Communication Technical Specifications

|

System: |

Chelton

Broadband Satellite System |

|

Antenna: |

HGA-7000

Electronically Steered Phased Array Antenna. |

|

Modem: |

Integrated

Airborne Modem/Router, 100 MB/s data rate |

|

Power

Amplifier: |

HPA-7400

Bi-directional Power Amplifier/Pre-Amplifier Short Coupled to the Phased

Array Antenna. |

|

Data Rate: |

Up to 332

kbs (Approximately 60 Kbs) Full Duplex

|

|

Constellation

Type: |

Fixed

Geo-Synchronous |

|

Coverage: |

Continuous

Coverage Over the Lower 48 States. |

|

Certification: |

FAA STC |

|

Power: |

28 vdc @ 10

amp full load |

|

Spin-up

Time: |

Less than 2

minutes from System Start |

|

Standards: |

TCP/IP |